High current connectors are crucial to the safe and efficient transmission of power in advanced vehicles and demanding industrial systems. As electric and premium vehicles become more popular, manufacturers across the electronics supply chain—from PCB assembly manufacturer operations to automotive tier suppliers—increasingly require robust connector solutions capable of supporting high currents and voltages. Companies like Promax in China stand at the forefront of providing custom-manufactured pogo pins, spring-loaded connectors, and high-current magnetic solutions to meet these growing requirements. This article offers a clear, concise guide to understanding high current connectors, their automotive applications, how they shape the performance of electric and luxury vehicles, and how to select and maintain the right connector for any project.

Key Takeaways

- High current connectors are essential for safe and efficient power transmission in electric and premium vehicles.

- Choosing the right high current connector involves considering current and voltage ratings, wire compatibility, and robust housing for harsh environments.

- Quality high current connectors, like those from Promax, improve EV performance by enabling efficient power delivery and faster charging.

- Proper installation—including correct torque, shielding, and environmental sealing—maximizes high current connector reliability and lifespan.

- Regular inspection and maintenance of high current connectors ensure ongoing safety, prevent overheating, and maintain stable operation.

What Is a High Current Connector?

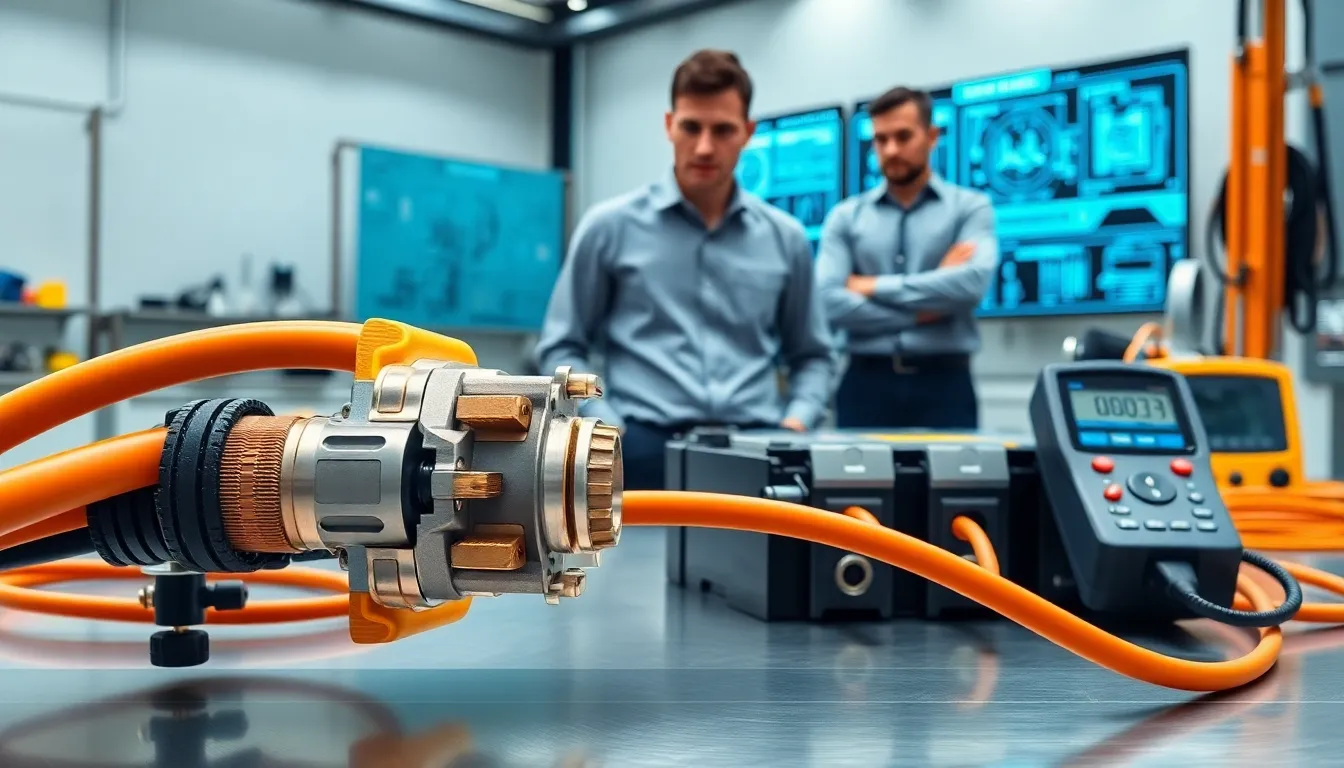

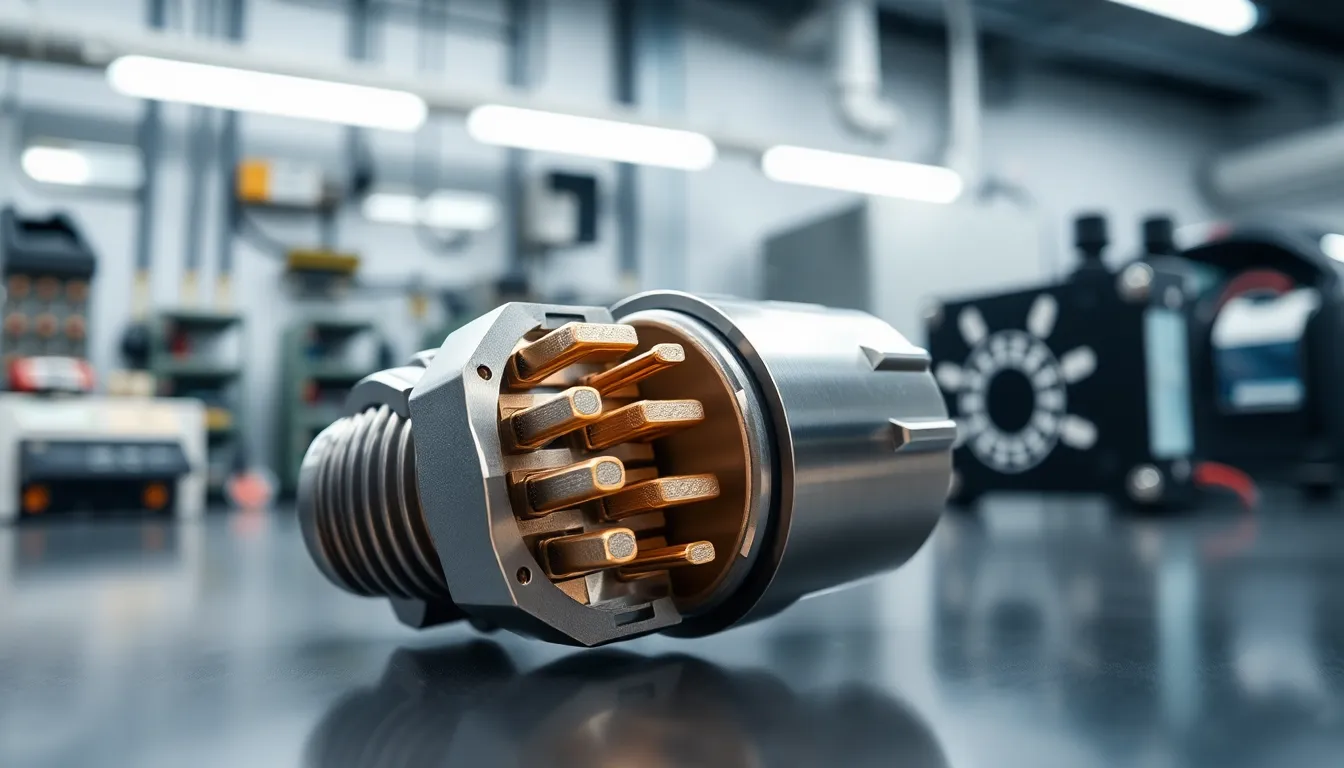

A high current connector is an electrical component specifically engineered to transmit large amounts of current, sometimes hundreds of amps, safely and reliably. These connectors feature durable contacts made from materials like copper alloys, often with silver or gold plating to reduce resistance and combat oxidation. Insulation, precise contact spacing, and robust housings prevent accidental short circuits and arcing, even at high voltages (ranging from 275V up to 1000V or more).

In manufacturing, the connector must maintain low impedance to ensure stable power delivery under sustained load without overheating. High current connectors serve a different purpose than standard signal connectors, they’re built for power, not just data. At Promax, they design and produce a wide range of custom high current connectors incorporating pogo pins, spring-loaded, and magnetic contact technologies, tailoring each solution to client specifications in automotive, industrial, and medical sectors.

Key Applications in the Automotive Sector

In the automotive world, high current connectors are fundamental for electric vehicles (EVs), hybrids, and an increasing number of premium vehicles with demanding electrical architectures. Their main roles include:

- EV Battery Connections: Safely linking high-voltage battery packs to drivetrain components, inverters, and power distribution units.

- Motor Power Delivery: Handling peak currents (often above 250A) for electric and hybrid propulsion systems.

- Service Disconnects and HV Fuses: Ensuring maintenance personnel can safely isolate high-voltage systems.

- DC Fast Charging Interfaces: Supporting rapid charging systems, such as CCS and CHAdeMO, which demand connectors that can withstand frequent, high-power charging cycles (up to 570A for heavy-duty EVs).

- 48V Systems: Used in mild hybrid or premium vehicles, high current connectors assist in efficiently powering electric turbos, active suspension, or advanced infotainment.

Promax‘s customizable connector solutions align with all these requirements, providing reliable performance and compatibility with specialized automotive standards around the world. Their manufacturing process allows for a range of wire cross-sections and flexible mounting solutions, critical for integration in modern vehicle platforms.

How High Current Connectors Impact Electric and Premium Vehicles

The quality and design of high current connectors directly affect the performance, safety, and appeal of electric and premium vehicles. Here’s how:

- Efficient Power Delivery: Low-impedance connectors minimize energy loss, allowing more of the battery’s power to reach motors and critical systems, extending vehicle range and supporting high-performance features.

- Faster Charging: High current connectors can safely handle rapid charging rates, for example charging an 80 kWh battery to 80% in around 30 minutes. This dramatically improves convenience for EV drivers and accelerates adoption of premium or electric models.

- Safety and EMI Protection: Shielded and well-designed connectors reduce electromagnetic interference (EMI). That’s crucial for systems with sensitive electronics or wireless features, often standard in high-end vehicles.

- High-Voltage Reliability: For powertrains running up to 1000V, connector stability prevents arcing, premature wear, and power loss.

Manufacturers like Promax integrate these design priorities into every assembly. By offering spring-loaded and custom magnetic contact solutions, they ensure optimal mating force, reduced insertion wear, and reliable performance under thermal and vibrational stress, key benefits for modern vehicles.

Important Factors When Choosing a High Current Connector

Selecting the correct high current connector requires an evaluation based on several quantifiable criteria:

- Current and Voltage Ratings: Choose a connector rated above the application’s peak current (in amps) and voltage requirements. Typical automotive units handle 275–1000V and up to 570A.

- Wire Size Compatibility: The connector’s contacts and terminals must match the gauge and insulation thickness of connecting wires (common sizes reach 150mm² for heavy EV applications).

- Contact Material and Plating: For longevity and stable resistance, opt for connectors with copper alloy bases and silver or gold surface finishes.

- Contact Spacing & Insulation: Ensure sufficient spacing to prevent voltage breakdown or shorting, especially in high-voltage propulsion systems.

- Robust Housing and Sealing: Protection against dust, oil, water, and oxidation is vital in automotive environments. Look for IP67/68-rated designs for underhood or chassis installations.

- Thermal and Mechanical Endurance: Verify that the connector is tested for resistance to vibration, heat cycles, and harsh under-vehicle conditions.

Promax manufactures high current connectors according to these criteria, working closely with OEM and tier-1 suppliers to tailor each connector to the exact system needs and space constraints.

Installation Tips and Best Practices

Proper installation is crucial for ensuring stable operation and long connector life:

- Follow Manufacturer Specifications: Always use the correct torque and insertion force specified by suppliers like Promax. This prevents fretting corrosion and ensures firm mating.

- Shielded Cable Integration: Use shielded connectors for systems where EMI suppression is essential, such as high-power drives or high-speed infotainment circuits.

- Wire Preparation: Strip and crimp or solder wires with the right tools, avoiding nicking or damaging conductors.

- Polarization & Keying: Select connectors with mechanical keying to prevent mismatching and accidental reversals.

- Regular Inspection: After installation, inspect for signs of incomplete mating, pin deformation, or compromised insulation.

- Environmental Sealing: Confirm that seals and gaskets are properly seated to keep out water, dust, and automotive fluids, especially for under-chassis connectors.

Promax provides detailed installation guidelines and can support clients with custom mounting hardware or design adjustments for challenging spaces.

Safety and Maintenance Considerations

High current connectors are designed to minimize risk and maximize system reliability, but regular maintenance is essential, especially in vehicle or industrial settings:

- Safety Features: Many connectors include shrouded contacts and insulation barriers to prevent accidental finger contact and arc flash.

- Low Impedance Paths: Maintenance checks should confirm that connections remain tight and resistance does not increase with wear, which could lead to overheating or energy loss.

- Physical Durability: Over time, connectors may experience wear from vibration, thermal cycling, and hundreds of connect/disconnect cycles. Signs of cracking, oxidation, or loosened pins should prompt replacement.

- Shielding and Grounding: Inspect shielding continuity to avoid EMI issues, particularly in EVs and connected vehicles.

- Cleaning and Lubrication: If recommended by the supplier, use approved contact lubricants for spring-loaded or pogo pin connectors, and clean contacts with lint-free swabs as needed.

Promax‘s connector solutions are engineered for longevity, with quality assurance testing to meet automotive and industrial safety benchmarks. Careful upkeep ensures long-term system stability and safety.

About Promax Pogo Pin

Spokesperson: Gavin

Position: Manager

Phone: (765) 705-7361

Email: tonyhoo@promaxpogopin.com

Location: 480 Jackson St, Gary, IN 46402, USA

Website: http://promaxpogopin.com/

Frequently Asked Questions About High Current Connectors

What is a high current connector and how is it used?

A high current connector is an electrical component designed to safely transmit large amounts of current, often hundreds of amps, in automotive and industrial systems. They feature durable contacts, robust insulation, and are commonly used in electric vehicles, power distribution units, and rapid charging interfaces.

Why are high current connectors important for electric vehicles?

High current connectors are crucial in electric vehicles because they efficiently deliver power from batteries to motors and support fast charging. Their robust design ensures safety and reliability, helping prevent overheating, arcing, and energy loss during operation.

How do I choose the right high current connector for my application?

To select the best high current connector, consider current and voltage ratings, compatibility with wire size, contact material, spacing for insulation, environmental sealing (IP67/68), and resistance to vibration. Always choose connectors rated above your peak application requirements for safety and longevity.

What maintenance is required for high current connectors?

Regular maintenance for high current connectors includes inspecting for loose connections, signs of wear, oxidation, or pin deformation. Ensure shielding is intact to avoid EMI issues and use approved lubricants or cleaning methods as recommended by the manufacturer to maintain optimal performance.

Can high current connectors be used in harsh environments?

Yes, high current connectors designed with robust housings and IP67/68 environmental sealing can be safely used in harsh automotive and industrial environments. They are engineered to resist dust, water, vibration, and temperature extremes—making them ideal for under-vehicle or outdoor installations.

What are the differences between standard and high current connectors?

Standard connectors are typically designed for signal or low-power transmission, while high current connectors are specifically engineered for delivering large amounts of power. High current connectors have greater insulation, robust contacts, and higher safety standards to manage and protect against high voltage and current loads.